Precision Manufacturing. Delivered.

Bridging the gap between world-class quality and on-demand speed. Every part, every time.

15 years of precision

Expert high-mix low-volume (HMLV) manufacturing.

Rapid, cost-effective delivery of complex parts at any volume.

Trusted by

Our Servise

Custom Prototype Service

Manufacturing Solutions for Global Innovators

REBAN delivers high-quality production parts through a blend of rapid tooling and refined manufacturing expertise.

• Speed: Rapid prototyping and on-demand tooling.

• Scale: Low-volume manufacturing tailored to your business.

• Quality: Expert in-house production and professional finishing.

• Value: Cost-effective solutions for local and international markets.

Why Choose Us

HOW TO WORK WITH US

To save our customers time and money, we have streamlined our production into four simple steps—taking you from prototype to delivered custom parts faster than ever.

Upload a CAD File

To start, simply select a manufacturing process and upload a 3D CAD file.

Get Quote with DFM

Within a few hours we'll send you design for manufacturability (DFM) analysis and real-time pricing.

Manufacturing Begins

Once you review your quote and place your order, we'll start the manufacturing process. We also offer finishing options.

Parts are Shipped!

Our digital manufacturing process allows us to produce parts in as fast as 1 day.

Blog

Blog & Latest Updates

The Evolution of CNC Machining and the Future of Precision Manufacturing In the landscape of modern industry, precision …

Technical Compendium: Subtractive vs. Additive Manufacturing Modern manufacturing is defined by the strategic application of two fundamentally different …

Frequently asked questions

At REBAN, we are committed to answering your queries about custom prototype service and our services.

What industries do you specialize in?

- Aerospace & Defense: Structural components, engine parts, and fasteners (compliant with AS9100 standards).

- Automotive & Transportation: Engine components, transmission parts, and custom tooling for EV/ICE vehicles.

- Medical Devices: Surgical instruments, implant components, and diagnostic equipment parts (ISO 13485 certified).

- Energy & Power Generation: Turbine parts, oil/gas exploration components, and renewable energy (wind/solar) hardware.

- Electronics & Semiconductor: Precision enclosures, heat sinks, and tooling for micro-electronics assembly.

- Precision Instruments & Automation: Robotic arm components, optical assembly parts, and high-tolerance machinery parts.

- Mold & Tooling: Custom injection molds, stamping dies, and jigs/fixtures for manufacturing.

What services do you offer?

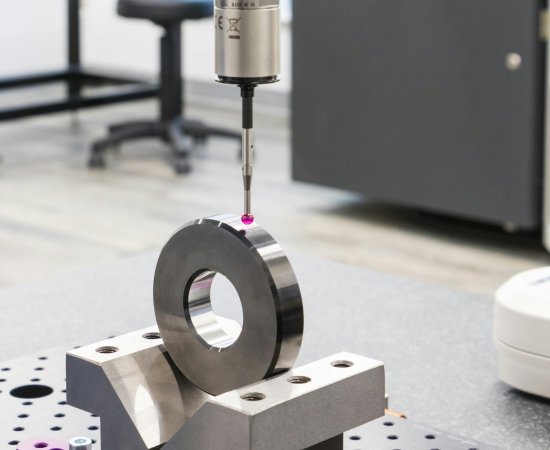

- CNC Machining: Precision multi-axis milling, turning, and complex part fabrication for tight-tolerance metal and plastic components.

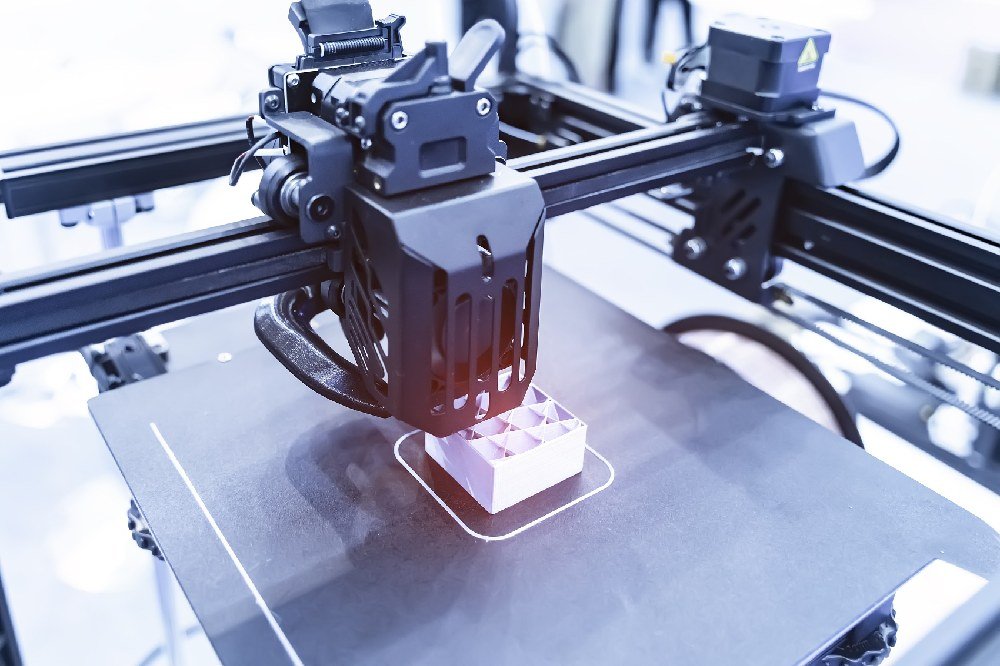

- 3D Printing: Rapid prototyping and low-volume production using advanced additive technologies (SLA, SLS, FDM, etc.) to accelerate design validation and iteration.

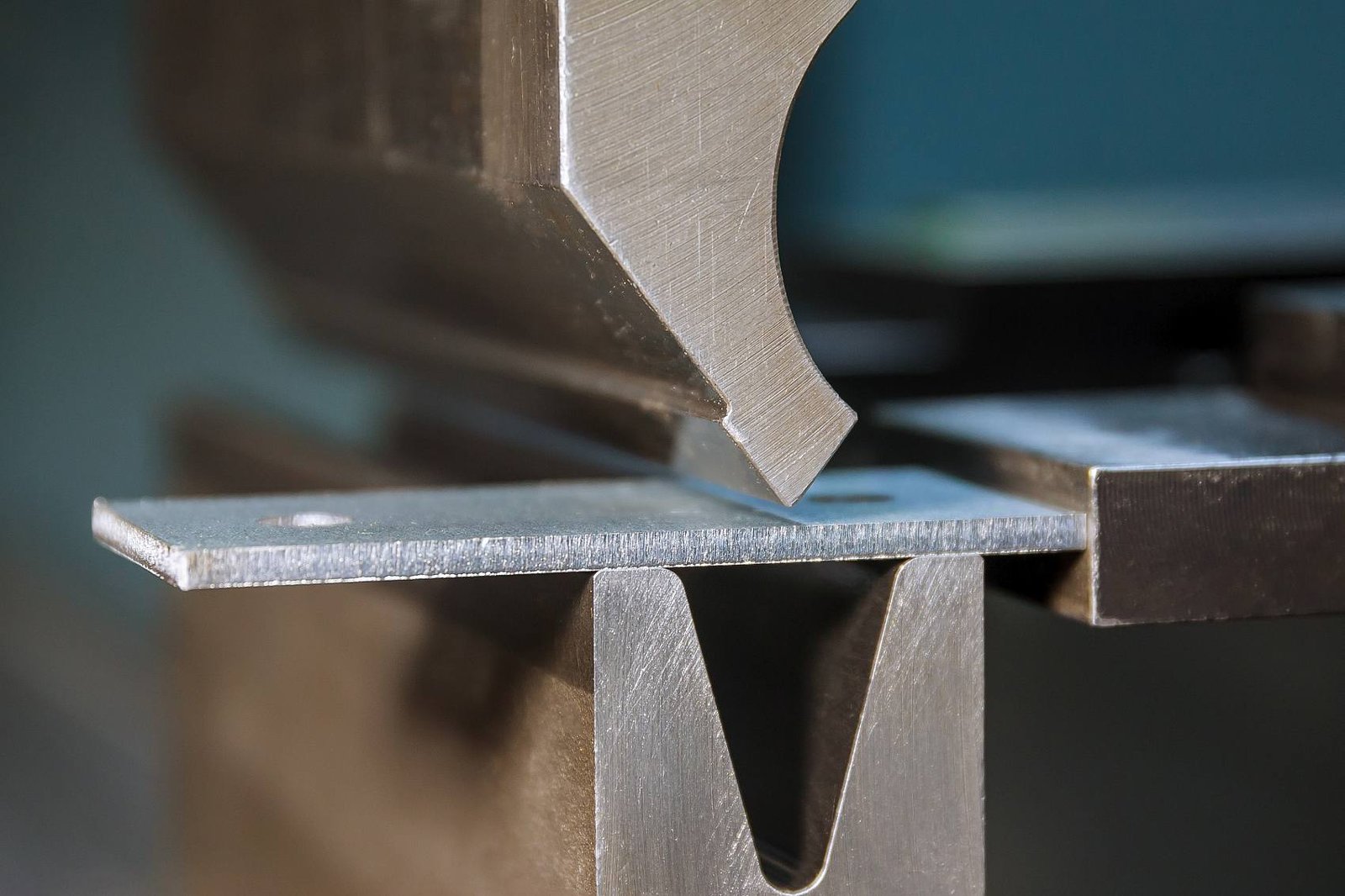

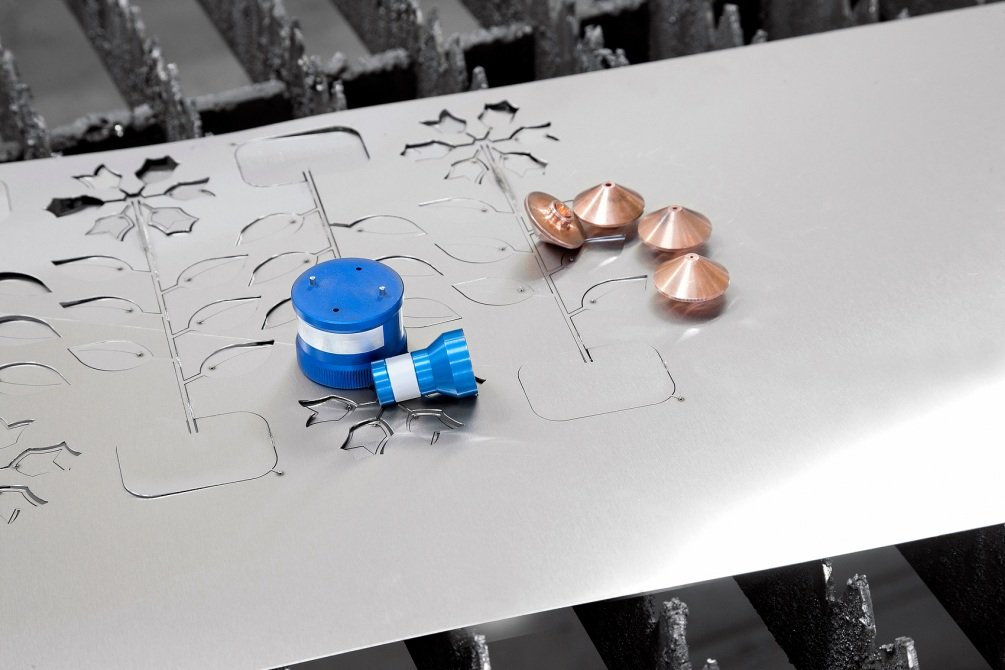

- Sheet Metal Fabrication: Custom cutting, bending, stamping, welding, and assembly of structural parts, enclosures, and brackets from various metal materials.

- Injection Molding: Mold design, tooling, and high-volume production of precision plastic components for industries like automotive, electronics, and consumer goods.

- Casting: Metal casting processes (including sand casting, investment casting, and die casting) for producing complex, durable metal parts with complex geometries.

- Surface Treatment: A full range of post-processing finishes, such as anodizing, plating, powder coating, sandblasting, passivation, and heat treatment, to enhance part durability, appearance, and performance.

How do you measure project success?

- Quality & International Compliance: First-pass inspection rate of ≥98% and scrap rate of ≤3%; 100% inspection for critical dimensions, full material traceability with material test certificates (MTC), and strict adherence to ISO 9001 quality standards.

- On-time Delivery (Critical for Exports): OTD rate of ≥95% for all order types (prototyping, small-batch, mass production); we reserve 10–15% of production capacity for rush orders and notify clients immediately of any potential delays to ensure on-schedule loading and shipping.

- Transparent Costing & Quotations: Cost variance within 5% of the quoted price, with no hidden fees; our detailed quotations clearly include packaging, standard export logistics and other associated costs, fully aligning with our global clients’ pricing and settlement preferences.

- Export Service & Communication: Prompt responses to design revisions and overseas inquiries (timely follow-ups via email/IM to accommodate cross-time zone collaboration); free rework or replacement for minor post-delivery issues, with clear resolution timelines.

- Export Compliance & Stable Production Capacity: Complete, accurate export documentation (commercial invoice, packing list, certificate of origin (CO), etc.) as requested; customized packaging and marking (shipping marks, neutral packaging) per client requirements; and compliance with environmental standards to meet the demands of certain overseas clients.

How can I get a quote?

- Submit your files: Share your 3D CAD (STEP/IGES/SolidWorks) and 2D drawings, including material specs, tolerances, and surface treatment requirements.

- Share project details: Let us know your order quantity (prototype/batch production), delivery timeline, and any certification or packaging needs.

- Get your quote: Within 24–48 hours, we’ll send a transparent quote with DFM (Design for Manufacturability) analysis, pricing, lead time, and MOQ.

- Confirm & start: Review and adjust the quote as needed, then approve to kick off sample or full production.