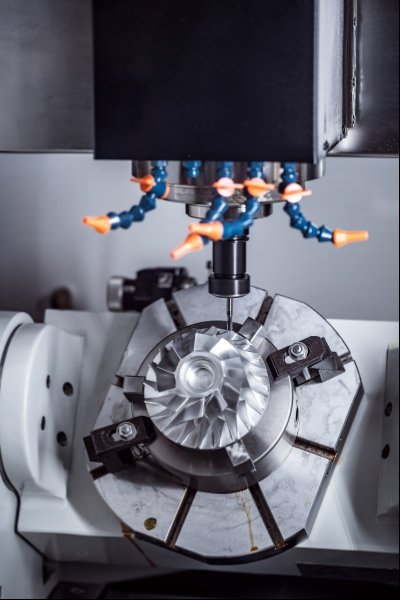

Ultra-High Precision CNC Machining

Achieving tolerances as tight as ±0.005mm with automated CNC technology. From surgical implants to aerospace components, REBAN delivers uncompromising accuracy.

Infinite Complexity

Absolute Tolerance

Rapid-Response Scale

Industry-Proven Reliability

What is Precision CNC Machining at REBAN?

- Micro-Tolerance Capabilities:We specialize in ultra-tight tolerances reaching±005 mm( ± 0.0002 in), ideal for complex assemblies.

- Multi-Axis Synchronicity:Our inventory includes 4-axis and 5-axis milling centers that produce intricate contours in a single setup, reducing fixture error and waste.

- Material Versatility:Expertise in machining high-strength alloys (Titanium, Inconel) and high-performance polymers (PEEK, Ultem).

- Compliance-Ready:Operations aligned with AS9100 (Aerospace), ISO 13485 (Medical), and IATF 16949 (Automotive)

Precision machining is more than just cutting material; it is a controlled subtractive process that produces consistent, high-fidelity parts that traditional machining cannot achieve. By utilizing advanced CAD/CAM integration and high-speed G-code automation, REBAN manufactures components with extreme dimensional stability for industries where failure is not an option.

Technical Capabilities & Tolerances

REBAN provides a one-stop solution by offering integrated secondary treatments in-house

Precision Machining Capabilities

- Multi-axis CNC machining for complex geometries

- Supports medical, aerospace, and automotive components

Tolerance Specifications

- Dimensional tolerance: ±0.005mm

- Concentricity: ≤0.002mm for cylindrical parts

Surface Finishing

- Ra 0.2μm–1.6μm (mirror polish, bead blasting, anodizing)

- Deburring and passivation for critical components

Precision Inspection

- CMM coordinate measuring

- Optical measurement and thread gauge verification

Technical Capabilities & Tolerances

REBAN utilizes a variety of specialized techniques to meet your project’s specific geometry.

| Process | Capabilities | Standard Tolerance |

|---|---|---|

| CNC Milling | 3, 4, & 5-axis; Face/Profile/Pocket Milling | ± 0.005 mm |

| CNC Turning | Straight/Taper turning, Threading, Form turning | ± 0.005 mm |

| Wire/Mirror EDM | Intricate internal shapes & ultra-hard materials | ± 0.002 mm |

| Surface Grinding | Achieving the smoothest finishes up to 63 μin | ± 0.001 mm |

Industry-Specific Precision Solutions

Aerospace & Defense

We machine high-strength, lightweight alloys that meet rigorous safety and regulatory standards.

- Focus:Critical dimensioning for engine components and structural flight hardware.

- Standard:AS9100 quality compliance.

Medical & Life Sciences

Revolutionizing medical prototyping with biocompatible materials and surgical-grade finishes.

- Focus:Custom orthopedic implants, surgical instruments, and dental components.

- Materials:Titanium, PEEK (ASTM compliant).

Tool & Die / Mold Making

Our specialized section for high-speed precision ensures reusable molds with exceptional longevity.

- Focus:Mirror EDM for high-gloss finishes and precision-fit injection molds.

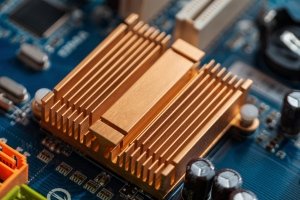

Electronics & Semiconductors

High-accuracy repeatability for high-volume production of miniature components.

- Focus:Connector pins, semiconductor housings, and RF shielding enclosures.

The REBAN Precision Workflow

1、Technical Consultation

- Our experts assist in material and manufacturing method selection to optimize your project’s value.

2、Advanced CAM Sequencing

- We sequence operations for maximum efficiency and cost-effectiveness.

3、In-Process Inspection

- Quality checks at every stage—from first-article inspection to final CMM verification.

4、Post-Finishing

- Comprehensive options including bead blasting, anodizing, and mirror polishing for functional and aesthetic excellence.

HOW TO WORK WITH US

Upload a CAD File

To start, simply select a manufacturing process and upload a 3D CAD file.

Get Quote with DFM

Within a few hours we'll send you design for manufacturability (DFM) analysis and real-time pricing.

Manufacturing Begins

Once you review your quote and place your order, we'll start the manufacturing process. We also offer finishing options.

Parts are Shipped!

Our digital manufacturing process allows us to produce parts in as fast as 1 day.