3D Printing Material Selection Guide: Engineering Your Vision

Select the ideal polymer or metal for your additive manufacturing projects. REBAN provides industrial-grade 3D printing solutions backed by the comprehensive material science ecosystem of South China’s high-tech manufacturing corridor.

Overview

Successful 3D printing begins with matching material properties to the part’s mechanical environment. At REBAN, we offer a spectrum of 30+ industrial resins, filaments, and powders. From rapid visual prototypes to flight-ready metal components, our selection covers the full lifecycle of product development.

1. Rigid Photopolymers (SLA/LCD)

Ideal for high-resolution prototypes with smooth surface finishes comparable to injection molding.

- Standard Resin: Perfect for aesthetic models and form-fit testing.

- Tough/Durable Resin: Simulates the properties of ABS or Polypropylene; excellent for snap-fits and enclosures.

- High-Temp Resin: Capable of withstanding temperatures up to 200°C+, ideal for mold inserts and heat-flow testing.

Mechanical Properties Comparison (SLA Resins)

| Resin Type | Tensile Strength (MPa) | Heat Deflection (°C) | Surface Quality | Best Application |

| Standard Clear/Gray | 40 – 55 | 50 | Excellent | Visual Prototypes |

| ABS-Like (Tough) | 55 – 65 | 65 | Very Good | Enclosures & Snap-fits |

| Ceramic-Reinforced | 60 – 75 | 250+ | Fair | Tooling & Molds |

| Flexible (80A) | 5 – 10 | N/A | Good | Gaskets & Grips |

2. Industrial Thermoplastics (FDM)

The workhorse for functional testing, jigs, and fixtures.

- PLA / PETG: Economical, dimensionally stable, and great for rapid concept validation.

- ABS / ASA: High impact resistance and UV stability (ASA). Ideal for outdoor automotive parts.

- PC (Polycarbonate): High-strength engineering plastic for rugged industrial environments.

- PEEK / PEI (Ultem): High-performance polymers for extreme thermal and chemical environments.

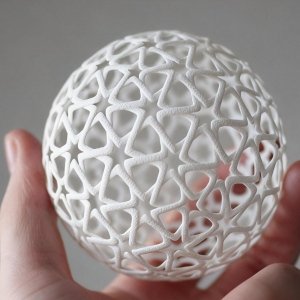

3. Nylon & Composite Powders (SLS/MJF)

No-support printing for complex geometries and end-use production parts.

- PA12 (Nylon): The industry standard for tough, functional parts with living hinges.

- PA11: Bio-derived nylon with higher ductility and impact resistance.

- Glass-Filled Nylon (PA12-GF): Enhanced stiffness and thermal stability for structural housings.

Nylon Performance Comparison

| Powder Grade | Density (g/cm³) | Elongation at Break (%) | Key Feature |

|---|---|---|---|

| PA12 (SLS) | 0.95 | 15 – 20% | Balanced Mechanics |

| PA12 (MJF) | 1.01 | 15 – 25% | Isotropic Strength |

| PA12-GF | 1.22 | 5 – 8% | Dimensional Rigidity |

4. Additive Metals (SLM/DMLS)

Direct metal laser melting for lightweighting and complex internal cooling channels.

- Aluminium (AlSi10Mg): Lightweight and good thermal properties for heat sinks.

- Stainless Steel (316L): Superior corrosion resistance for medical and chemical applications.

- Titanium (Ti6Al4V): High strength-to-weight ratio for aerospace and orthopedic implants.

- Cobalt Chrome: High wear resistance for dental and medical industries.

Get Your Industrial 3D Printed Parts from REBAN

Choosing the right 3D printing material isn’t just about hardness. You need to consider heat resistance, chemical compatibility, and strength over time. At REBAN, we use data and expertise to help you select the perfect material for your project.

Our facility uses advanced industrial 3D printing technology. We guarantee the quality and consistency of your parts—whether you need one prototype or thousands of final production components.

Get a precise, reliable quote for your project. Talk to our team today.