High-Precision CNC Turning Services

Cylindrical Perfection

Micron-Level Precision

Rapid Global Scale

Hybrid Complexity

Unlocking Micron-Level Performance: The REBAN Turning Standard

While typical shops offer basic lathes, REBAN operates as a Precision Engineering Partner. We bridge the gap between high-complexity design and cost-effective manufacturing.

- Ultra-Tight Tolerances: We consistently hold tolerances as tight as ±005mm, utilizing climate-controlled machining centers to eliminate thermal expansion errors.

- Advanced Live Tooling: One-stop machining for radial features and complex threads. By combining milling and turning, we guarantee superior precision with faster, more cost-effective turnarounds.

- Superior Surface Integrity: Turning naturally produces superior finishes compared to milling. We achieve “Ready-to-Assemble” surfaces that often require no post-processing.

- Scalable Production Advantage: Whether you need a single prototype or a global rollout, our streamlined manufacturing model reduces overhead, passing 30–50% savings directly to you.

Comprehensive CNC Turning Capabilities

Our facility is optimized for speed and geometric versatility, supporting both 2-axis turning and complex multi-tasking operations.

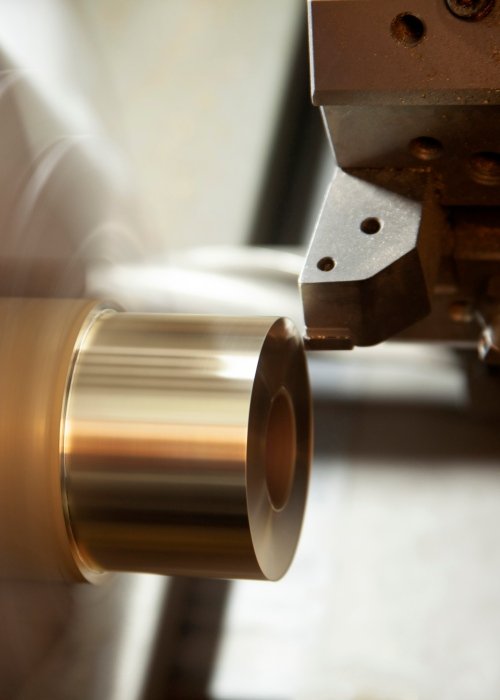

Precision Lathe Operations

Ideal for high-speed production of cylindrical parts, shafts, and bushings with exceptional concentricity.

Live Tooling (Mill-Turn)ties

The elite choice for parts requiring secondary milling features (hexagons, cross-holes, and grooves) without removing the part from the spindle.

ID & OD Threading

Advanced capabilities for internal and external threading, including blind internal threads and specialized custom pitches.

50+ Certified Materials: From Plastics to Super-Alloys

We source traceable, certified raw materials to ensure your components thrive in high-stress environments.

- Metals: Aluminum (6061/7075), Stainless Steel (303, 304, 316L), Titanium (Gr5), Brass, Copper, and Steel Alloys (4140).

- High-Performance Plastics: PEEK, Ultem (PEI), Delrin (POM), Nylon, Polycarbonate, and PMMA (Acrylic).

Advanced Surface Finishes

REBAN provides a one-stop solution by offering integrated secondary treatments in-house:

- As-Machined: Smooth, concentric toolmarks (superior to milling).

- Bead Blasting: Fine matte finishes to remove slivers and break edges.

- Anodizing (Type II & III): Certified to MIL-A-8625 (Black, Clear, and custom colors).

- Chemical Plating: Chromate Plating (MIL-DTL-5541), Electroless Nickel, and Passivation.

| Parameter | Specification |

|---|---|

| Standard Tolerances | Metals: ISO 2768-fine |

| Tightest Tolerance | Up to ±0.005mm (0.0002″) |

| Max Part Size | ∅ 200mm x 500mm (7.9″ x 19.7″) |

| Min Feature Size | ∅ 0.05mm (0.00197″) |

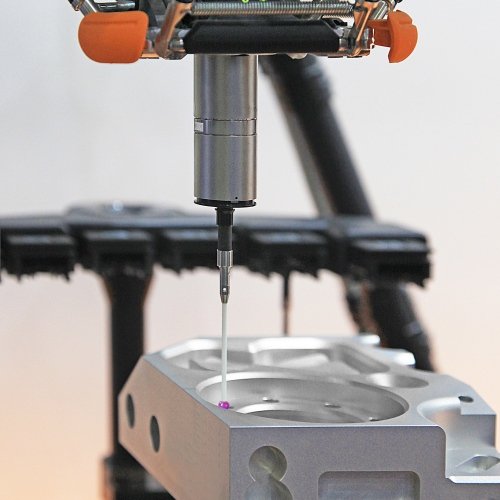

| Quality Control | CMM Inspection, FAI Reports, AS9100/ITAR Compliant Networks |

Driven by Creativity

Global Logistics, Doorstep Delivery

3-Day Fast-Track Delivery

Direct express shipping to the USA, EU, and Asia.

DDP Shipping Options

We handle all duties, taxes, and customs paperwork—transparent and hassle-free.

Proactive Engineering Partnership

Minimize risks with real-time DFM feedback. Our proactive design optimization ensures your complex concepts are production-ready, reducing costs and lead times 24/7.

HOW TO WORK WITH US

Upload a CAD File

To start, simply select a manufacturing process and upload a 3D CAD file.

Get Quote with DFM

Within a few hours we'll send you design for manufacturability (DFM) analysis and real-time pricing.

Manufacturing Begins

Once you review your quote and place your order, we'll start the manufacturing process. We also offer finishing options.

Parts are Shipped!

Our digital manufacturing process allows us to produce parts in as fast as 1 day.