Injection Molding Material Intelligence Guide

High-Performance Polymers & Precision Chemistry for Global Manufacturing

In the high-stakes world of mass production, material selection dictates the success of your product’s lifecycle. REBAN combines the agility of rapid tooling with the scientific rigor of polymer engineering. We specialize in processing high-performance thermoplastics that meet global standards including UL, RoHS, REACH, and FDA.

Overview

At REBAN, we bridge the gap between material science and manufacturing reality. Our facility specializes in processing everything from high-fluidity resins for complex thin-wall electronics to reinforced composites for structural automotive components. We ensure every shot meets your specific requirements for shrinkage, impact resistance, and aesthetic finish.

1. High-Performance Engineering Series

These materials are the backbone of structural innovation, designed to replace metal components and reduce weight.

- PA6/PA66 (Nylon) + Glass Fiber (15%-50% GF): By adding glass fibers, we significantly increase the tensile strength and heat deflection temperature (HDT). Ideal for automotive engine covers and industrial tool housings.

- PBT (Polybutylene Terephthalate): Exceptional electrical insulation and resistance to chemical cleaning agents. Essential for high-voltage EV connectors and switchgear.

- POM (Polyoxymethylene/Acetal): Known for its high stiffness, low friction, and excellent dimensional stability. The go-to material for precision gears and sliding mechanisms.

2. Advanced Aesthetics & Optical Resins

For consumer electronics and medical devices where surface finish and clarity are paramount.

- PMMA (Acrylic): Offers the highest light transmission among plastics (92%). Used for light pipes, automotive tail lights, and optical displays.

- PC (Polycarbonate) – High Flow Grades: Engineered for thin-walled mobile phone frames and laptop housings, providing high impact resistance without the bulk.

- SAN/AS: Provides better chemical resistance than PS while maintaining transparency; widely used in kitchenware and cosmetic packaging.

3. The "Super" Polymers: Extreme Environments

When the operating environment involves extreme heat or aggressive chemicals.

- PEEK (Polyetheretherketone): One of the highest performing thermoplastics in the world. Capable of continuous use at 240°C. Common in aerospace manifolds and medical implants.

- PPS (Polyphenylene Sulfide): Highly crystalline with a melting point of 280°C. It is inherently flame retardant and resistant to almost all organic solvents.

- LCP (Liquid Crystal Polymer): Features exceptional flow for ultra-miniature electronic connectors with pitch distances below 0.5mm.

Technical Performance Matrix (Expanded)

| Material Category | Specific Grade | Tensile Strength (MPa) | HDT @ 1.8MPa (°C) | Molding Shrinkage (%) | Key Advantage |

|---|---|---|---|---|---|

| General Purpose | ABS (High Gloss) | 45 | 82 | 0.4 – 0.7 | Superior Finish |

| Transparent | PC (Optical) | 65 | 135 | 0.5 – 0.7 | Impact & Clarity |

| Reinforced | PA66 + 30% GF | 170 | 250 | 0.3 – 0.5 | Structural Rigidity |

| Friction/Wear | POM (Copolymer) | 62 | 110 | 1.8 – 2.2 | Self-Lubricating |

| Chemical Resist | PBT (Unfilled) | 55 | 60 | 1.5 – 2.0 | Electrical Stability |

| Extreme Temp | PEEK (GF30) | 150+ | 315 | 0.1 – 0.2 | Aerospace Grade |

4. Specialized Overmolding & Elastomers (TPE/TPU/LSR)

REBAN excels in multi-shot (2K) molding, bonding soft-touch surfaces to rigid substrates.

- TPE/TPU: Provides ergonomic grips, vibration dampening, and non-slip surfaces.

- Liquid Silicone Rubber (LSR): Offers extreme thermal stability and biocompatibility. Ideal for medical seals and wearable tech.

- Bonding Optimization: We select compatible grades of ABS/PC and TPE to ensure chemical bonding without the need for mechanical interlocks.

Mastering the Polymer Matrix

At REBAN, materials are the structural DNA of your product. We specialize in the complex transition from resin pellet to functional part, blending advanced polymer rheology with high-precision manufacturing. Whether you are optimizing for automotive impact safety or ultra-thin electronic housings, our material intelligence ensures your vision is realized with absolute mechanical fidelity.

Our Polymer Integrity Standards

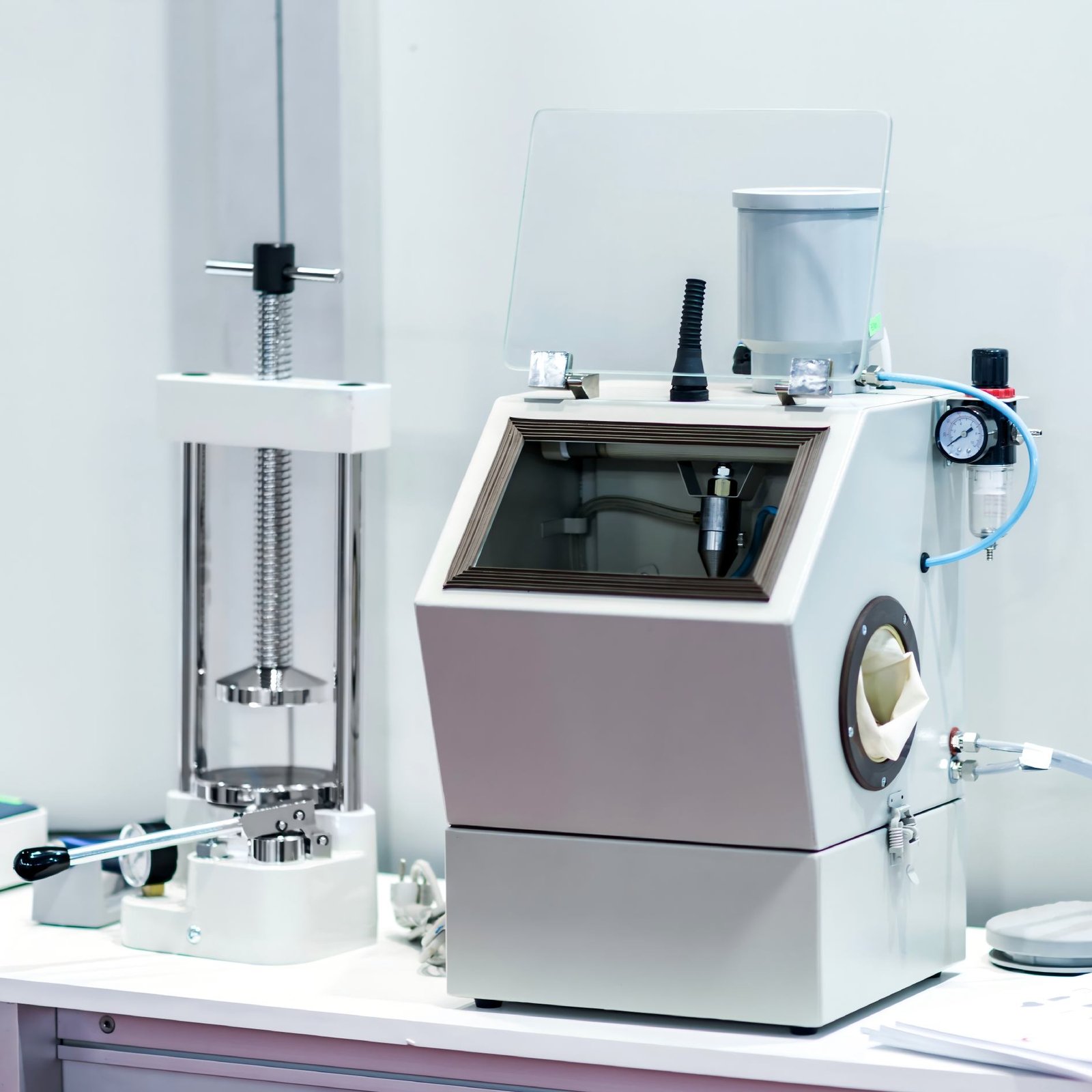

Scientific Validation: Every resin grade is verified for Melt Flow Index (MFI), moisture content, and shrinkage to ensure predictable performance.

Engineering-Driven Selection: We provide custom compounding, including GF/CF reinforcement, UV stabilization, and UL94-V0 flame retardancy.

Batch Consistency: Closed-loop feeding and real-time drying protocols guarantee that the 1,000,000th part maintains the exact properties of the first.