Low-Volume CNC Machining & Small-Batch Production

Bridge the Gap from Prototype to Production—No Tooling, No MOQ. Turn CAD models into high-quality production parts in as fast as 24–72 hours. Scale your business with cost-effective small batches and professional DFM support.

Save 30% on Average

Precision to ± 0.001mm

1 to 100,000+ Units

3-Day Rapid Prototyping

What is Low-Volume CNC Manufacturing?

Low-volume manufacturing (from 1 to 100,000+ units) serves as your critical “Bridge to Production.” It enables you to launch faster, validate market demand, and refine designs—all without the high capital investment or lead times of permanent mass-production tooling.

- Bridge Manufacturing: Transitioning smoothly from prototype to full-scale assembly.

- Custom Low-Demand Parts: High-mix, low-volume components for specialized industries.

- Pilot Runs: Validating market fit before investing in expensive tooling.

- Rapid Iteration: Designs that require frequent functional updates.

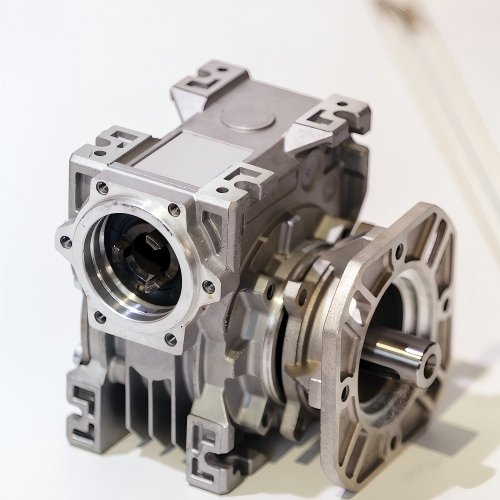

Our Small-Batch Machining Capabilities

Equipped with cutting-edge technology to ensure consistent, repeatable quality across every unit.

| Process | Technical Focus | Best For |

|---|---|---|

| 5-Axis Milling | Simultaneous 5-axis movement | Intricate geometries & rapid setups |

| CNC Turning | Precision cylindrical machining | Shafts, connectors, and radial features |

| Swiss Machining | Sliding headstock technology | Close-tolerance miniature parts (Medical/Electronics) |

| Wire & Sink EDM | Electric discharge erosion | Detailed shapes in hardened tool steels |

| Honing & Grinding | Abrasive finishing | Ultra-precise flatness and Ra surface quality |

From Concept to Scaled Production

We have streamlined our workflow to ensure your project moves from digital file to physical part with zero friction.

CAD/CAM Programming

- We convert your 3D models into optimized CNC instructions, ensuring maximum toolpath accuracy.

Material Selection

- Choose from 50+ metals and plastics, including Aerospace-grade Aluminum, Titanium, and biocompatible PEEK.

Precision Machining

- Utilizing automated workflows to produce uniform parts with minimal dimensional deviation.

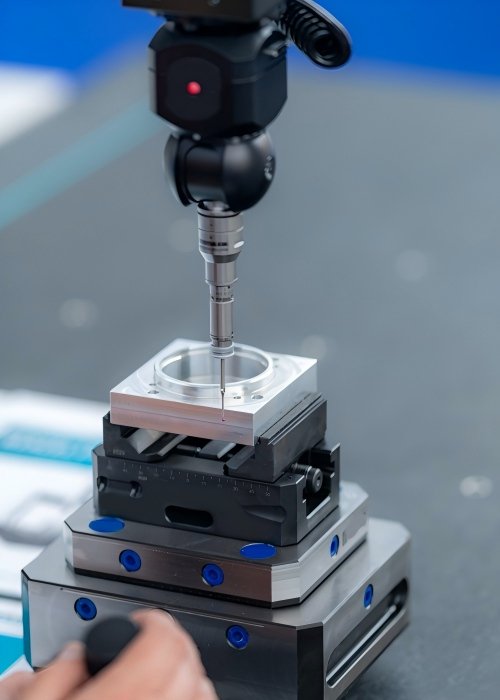

Finishing & Inspection

- Parts are deburred, surface-treated (Anodized/Powder Coated), and undergo CMM inspection to ensure IATF 16949 compliance.

HOW TO WORK WITH US

Upload a CAD File

To start, simply select a manufacturing process and upload a 3D CAD file.

Get Quote with DFM

Within a few hours we'll send you design for manufacturability (DFM) analysis and real-time pricing.

Manufacturing Begins

Once you review your quote and place your order, we'll start the manufacturing process. We also offer finishing options.

Parts are Shipped

Our digital manufacturing process allows us to produce parts in as fast as 1 day.