Manufacturing on Demand for Medical & Beauty Devices

ISO 13485:2016 Certified Partner to Global Healthcare Innovators and Premium Aesthetics Brands

Precision-Engineered Components and High-Elegance Applications

Global Production Scale, Medical-Grade Rigor

Leverage the high-tech manufacturing ecosystem specialized in precision medical instruments. REBAN provides instant access to production lines capable of maintaining the ultra-tight tolerances required for surgical tools and the superior surface finishes essential for high-end beauty technology.

Expert DFM for Medical Hardware

Navigate complex geometry requirements with our engineering-led Design for Manufacturing (DFM) reviews. Receive detailed feedback on biocompatible material selection, wall thickness for sterilization durability, and precision assembly fits. Our technical team works directly with your STEP, Parasolid, and SolidWorks files to ensure seamless engineering integration and regulatory compliance.

Quality Assurance & Regulatory Compliance

We prioritize patient safety and device efficacy. Our facilities are certified to ISO 13485:2016 and ISO 9001:2015. We provide comprehensive documentation packages including Certificate of Compliance (CoC), Material Mill Test Reports, Biocompatibility Certs (USP Class VI), and Full Dimensional Inspection via automated CMM.

Innovate Faster in Healthcare and Aesthetics

From ergonomic surgical handles to complex cooling systems for laser aesthetic devices, our on-demand platform ensures your hardware meets the highest clinical and aesthetic standards.

Top Medical & Beauty Applications

Surgical Robotics & Tools: High-precision end-effectors, robotic arm joints, and ergonomic scalpel handles.

Diagnostic & Lab Equipment: Aluminum chassis for MRI/CT components, microfluidic manifolds, and centrifuge rotors.

Aesthetic Laser & RF Devices: Liquid-cooled handpiece housings, internal optical mounts, and high-finish outer shells.

Wearable Health Tech: Biocompatible enclosures for heart rate monitors and smart medical patches.

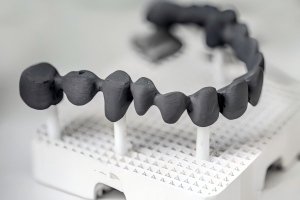

Dental Technology: Titanium implants, orthodontic alignment fixtures, and handpiece components.

Clinical Models: Anatomically accurate 3D printed models for preoperative planning and training.

Specialized Manufacturing Capabilities

Precision CNC Machining

Nano-level accuracy for critical implants and laboratory hardware.

Medical Metals: Titanium Grade 5 (Ti-6Al-4V), Stainless Steel 316L (Surgical Grade), and Cobalt-Chrome.

Medical Plastics: PEEK (for sterilization cycles), Ultem (PEI), and medical-grade Delrin.

Performance: Tight tolerances up to 0.005mm for mission-critical assemblies.

Advanced Medical Injection Molding

Scale from pilot runs to mass production in ISO-certified cleanrooms.

Materials: USP Class VI compliant Resins, Liquid Silicone Rubber (LSR) for seals, and antimicrobial plastics.

Capabilities: Overmolding for soft-touch surgical grips and insert molding for complex electronic integration.

High-Fidelity 3D Printing (Additive Manufacturing)

Complex geometries for patient-specific solutions and rapid functional testing.

Micro-SLA/DLP: 25-micron layer resolution for microfluidic devices and hearing aid components.

Metal DMLS: 3D printed Titanium for topologically optimized orthopedic implants.

Material Comparison: Medical & Beauty Grade Substrates

| Material | Biocompatibility | Sterilization Performance | Primary Application |

|---|---|---|---|

| Titanium Grade 5 | Excellent | Autoclave/Gamma Stable | Orthopedic Implants & Surgical Tools |

| PEEK (Medical Grade) | Excellent | Repeated Autoclave cycles | Spinal Cages & Dental Abutments |

| Stainless Steel 316L | High | High Corrosion Resistance | Surgical Instruments & Aesthetic Probes |

| Aluminum 6061-T6 | N/A (Non-Contact) | Anodizing required | Beauty Device Chassis & Lab Hardware |

Medical & Beauty Post-Processing Capabilities

- Electropolishing: For ultra-smooth, burr-free surgical surfaces.

- Passivation: Enhancing corrosion resistance for stainless steel instruments.

- Hard Anodizing: Type III coatings for durable, wear-resistant medical frames.

- Laser Marking: Permanent UDI (Unique Device Identification) and logo etching.

- Class 10k Assembly: Final assembly and sterile-ready packaging.